THREADED BIT - DRIFTER - R28 ( 1 1/8” )

THREADED BIT - DRIFTER - R28 ( 1 1/8” ) Specification

- Cutting Area

- Rock drilling applications

- Dimension (L*W*H)

- Standard dimensions for R28 threaded bit

- Diameter

- 1 1/8 inch (28mm)

- Machine Type

- Drifter

- Condition

- New

- Noise Level

- Typical for rock drilling bits

- Features

- Threaded for secure fitting durable for rock drilling

- Product Type

- Threaded Bit

- Material

- High-grade steel/copper

- Computerized

- No

- Automatic Grade

- Manual

- CNC Or Not

- Not CNC

- Control System

- Manual

- Power Source

- Mechanical system

- Weight (kg)

- Varies based on dimensions and material

- Capacity

- Standard

- Color

- Copper

- Usage & Applications

- Rock drilling and mining

About THREADED BIT - DRIFTER - R28 ( 1 1/8” )

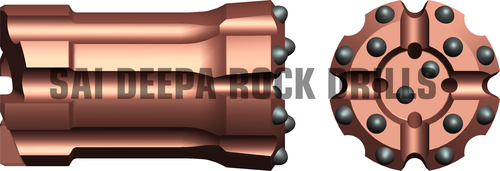

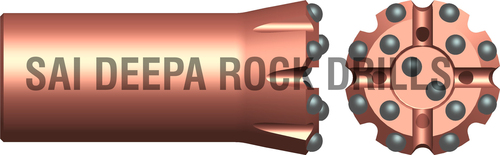

| R28 ( 1 1/8 ) THREAD BITS | |||||||

| BUTTON BIT REGULAR | |||||||

| BIT DIAMETER | BUTTONS QTY X SIZE,MM | ANGLE 0° | FLUSHING HOLE | PRODUCT NO | |||

| MM | INCH | GAUGE | FACE | FACE | SIDE | ||

| 38 | 1 1/2" | 4x9 | 2x8 | 25 ° | 2 | 0 | 46-3422038YS |

| 41 | 1 5/8 | 5 x 9 | 2 x 8 | 30 ° | 1 | 1 | 46-3521041YS |

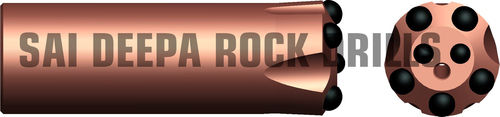

Superior Durability for Rigorous Tasks

Manufactured from high-grade steel and copper, the THREADED BIT - DRIFTER - R28 delivers outstanding lifespan and wear resistance. Its secure threaded connection makes this bit an ideal choice for sustained rock drilling operations, reducing downtime and maintenance costs.

Precision Engineered for Drifter Machines

Specifically designed for use with drifter machines, this threaded bit offers optimal performance in both mining and rock drilling. Each bit is built to the standard R28 specification, assuring a precise fit and consistent drilling results for a variety of application demands.

Easy Integration and Reliable Operation

Without automation or computerized controls, this bit is straightforward to install and operate manually. Its standard dimensions and mechanical power compatibility allow for quick integration with existing setups, simplifying the drilling process and enhancing productivity.

FAQs of THREADED BIT - DRIFTER - R28 ( 1 1/8 ):

Q: How is the THREADED BIT - DRIFTER - R28 installed on drilling equipment?

A: The bit is designed with a standard R28 thread, ensuring quick and secure attachment to compatible drifter machines using manual tools. This allows for fast setup and changeovers during drilling operations.Q: What materials are used in the construction of this rock drilling bit?

A: The bit is crafted from high-grade steel and copper, providing excellent strength and resistance to abrasion, which is crucial for rock drilling and mining environments.Q: When should I choose the R28 threaded bit for my project?

A: The R28 threaded bit is ideal for rock drilling and mining applications where durability, secure fitting, and efficient manual operation are required, particularly in conditions that demand robust, non-computerized tools.Q: Where can this threaded bit be used effectively?

A: It excels in rock drilling applications and mining environments, making it suitable for use in mining sites, quarries, and construction projects that involve substantial rock penetration.Q: What is the main benefit of using a threaded bit for rock drilling?

A: Threaded bits provide a secure, vibration-resistant connection to the drilling machine, enhancing operational safety, prolonging bit life, and maintaining drilling accuracy.Q: How does the manual operation impact the process?

A: Manual operation gives the user direct control over the drilling process, allowing for adjustments in real-time and making the bit compatible with a range of mechanical drilling systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drifter Bits & Retract Bits Category

THREADED BIT - RETRACT - T38 ( 1 1/2” )

Condition : New

Features : Threaded bit retract design durable material precision cutting

Material : Highgrade alloy steel

Product Type : Threaded Bit

Usage & Applications : Mining drilling and excavation

Automatic Grade : Manual

THREADED BIT - RETRACT - T45 ( 1 3/4” )

Condition : New

Features : Threaded design Retractable bit

Material : Steel

Product Type : Drill Bit

Usage & Applications : Mining Quarrying Construction

Automatic Grade : Manual

T60 ( 2 5/16” ) DRIFTER

Condition : New

Features : Drifter rod suitable for rock drills

Material : Highgrade alloy steel

Product Type : Drifter Rod

Usage & Applications : Mining Quarrying and Construction

Automatic Grade : SemiAutomatic

THREADED BIT - DRIFTER - R25 ( 1” )

Condition : New

Features : Threaded Bit for Drifter Durable Design

Material : Alloy Steel

Product Type : Threaded Bit

Usage & Applications : Rock Drilling Mining Operations

Send Inquiry

Send Inquiry